Innovative Microplastics Detection & Identification Sensor Developed at WHOI

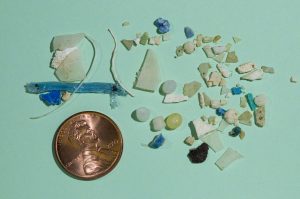

Microplastics are defined as plastic fragments less than five millimeters in size. These tiny particles have become a growing concern in recent years due to their potential effects on everything from marine life to the water we drink. However, despite growing concern, their impact is still largely unknown due to the lack of technological advancement in detecting and identifying microplastics.

During the summer of 2021, the Office for Technology Transfer at Woods Hole Oceanographic Institution collaborated with graduate students at Tufts Gordon Institute to identify current tools used for microplastics detection and opportunities for innovation. The graduate team determined that microplastics concerns are no longer limited to scientists and researchers looking to understand potential impacts but are also emerging across various industries. The team also found that currently available technologies, particularly those offering high levels of accuracy, are large, costly, and not field portable. As researchers try to determine just what type of impact microplastics may have on our health and the planet, industries like biomedical, food & beverage, and water treatment are also looking at ways to determine their presence, offering opportunities for innovation.

There are a variety of methods currently available to detect and analyze microplastics. According to Technology Networks, about “50% of microplastics researchers use Fourier-transform infrared spectroscopy (FT-IR), 32.5% visual inspection, and 10% Raman spectroscopy for the detection of microplastics” (Bose). Other researchers use techniques such as electron microscopy and gas-chromatography spectroscopy. Deciding which method to use depends on the particle size and environment being studied.

However, the challenge with commercially available sensors is that two of the most utilized methods, FT-IR, and RAMAN, are time-consuming, relatively expensive, or not reliable for smaller particle sizes. The challenges presented with FT-IR and RAMAN hinder the development of microplastics analysis standards. Outside of laboratories and research, other industries cannot adopt expensive and time-consuming technology.

Collected plastic samples compared in size to a penny.

Photo by Tom Kleindinst © Woods Hole Oceanographic Institution

WHOI scientist Dr. Anna Michel and Ph.D. student Beckett Colson are developing a more cost-effective method for detecting and quantifying microplastics – the Microplastics Impedance Spectrometer Sensor. The sensor is a flow-through detection process for microplastics study; it differentiates between plastic and non-plastic particles in a liquid sample. The WHOI-developed sensor utilizes Quantum-Cascade Lasers – unlike pricier, time-consuming existing methods, such as FT-IR and RAMAN – to make rapid detections in minutes without the possibility of contaminating the sample.

The WHOI team has partnered with Triple Ring Technologies to advance the sensor and develop a portable field system – helping move precise microplastics detection out of the lab.

To learn more about the development and advancement of the microplastics sensor in collaboration with Triple Ring Technologies or additional funding & support, please see the press release here.

Please visit the technology listing page for more information on the microplastics detection sensor.

For more information on licensing, please contact Allison Markova at amarkova@whoi.edu.